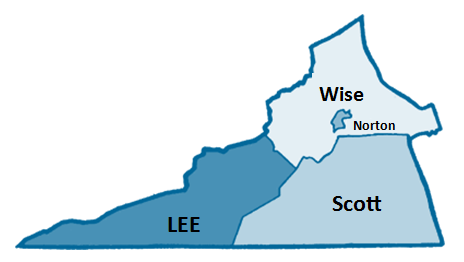

The LENOWISCO region of Virginia, being considered for future SMR siting, is in the far southwestern corner of the state. (Image: Virginia.gov )

Seven sites in southwestern Virginia have been identified as “competitive hosting grounds” for small modular reactors by a feasibility study Dominion Engineering, Inc. (DEI) prepared for the LENOWISCO Planning District Commission. (The planning district, based in Duffield, Va., serves the counties of Lee, Wise, and Scott and the city of Norton.) At a May 22 press conference at LENOWISCO’s offices, DEI chemical engineer and principal investigator Chuck Marks said the review represents the “very early stages of, does this region have what it takes to site one of these reactors, successfully deploy and successfully operate. And the answer is overwhelmingly yes,” according to an article in the Cardinal News.

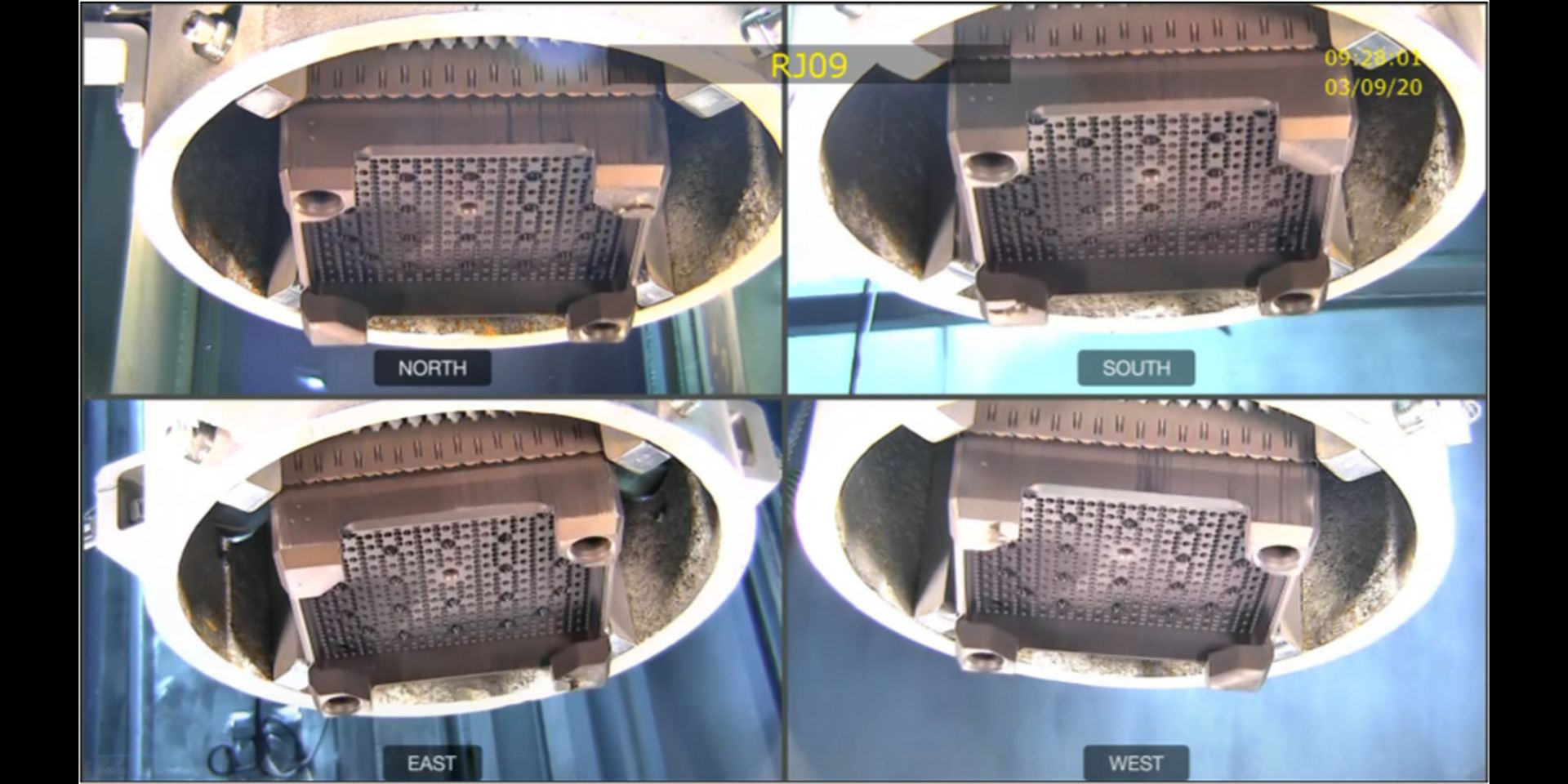

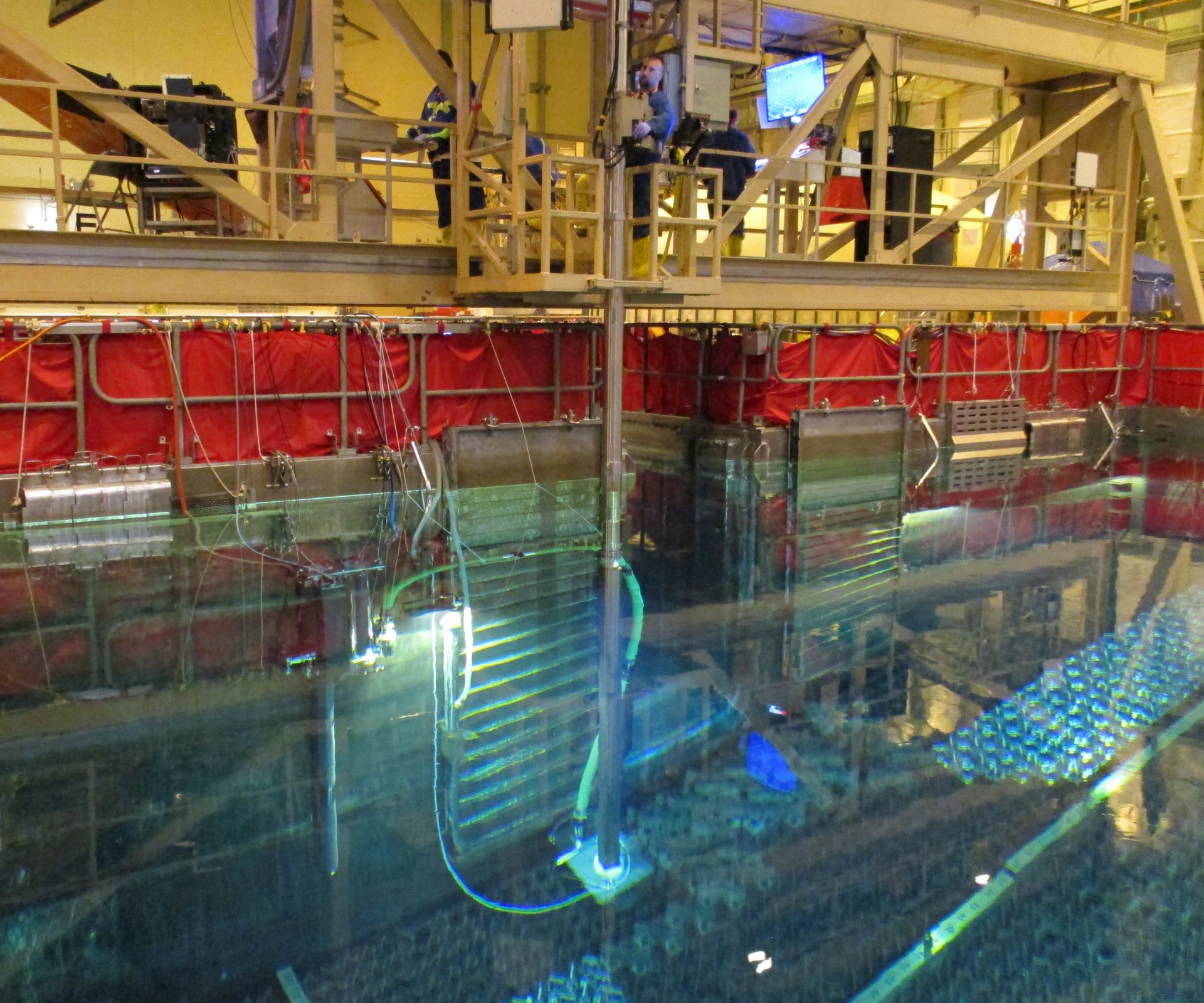

In the midst of the COVID-19 pandemic, U.S.-based experts from Dominion Engineering led European workers remotely in the execution of ultrasonic fuel cleaning.

Around the world in the mid-March time frame, conditions were changing rapidly due to the COVID-19 pandemic, as was everyone’s understanding of it. For nuclear power plants, the pandemic meant dealing with new government regulations and restrictions that were put in place. “U.S.-based support of international clients was especially challenging,” said Mike Little, president and principal officer of Reston, Va.–based Dominion Engineering Inc. (DEI). “With border closures going into effect, we were not only focusing on the health and safety of our workers abroad, but also making sure they would be able to return home. Providing remote subject matter expertise from the U.S. through our international service partners was critical to successful job execution during this time.”

Allied Power has acquired Dominion Engineering, Inc. (DEI), Allied announced last week. Financial terms of the deal were not disclosed.

Allied Power has acquired Dominion Engineering, Inc. (DEI), Allied announced last week. Financial terms of the deal were not disclosed.